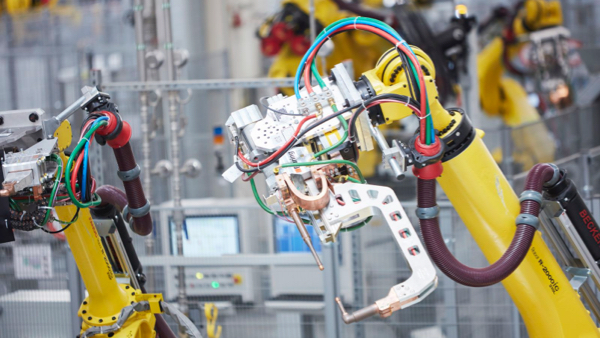

Revolutionizing Automotive Manufacturing with Cutting-Edge Digital Twin Technology

Pioneering Luxury and Innovation

BMW iFACTORY Strategy:

A Leap Towards Future Automotive Production

Accelerated Development Through Virtual Planning

AI Simulation Technology: Driving Intelligent Manufacturing of the All-New BMW 5 Series

Redefining Automotive R&D with AI Simulation

Comprehensive Applications in Automotive Development

LarkXR | 3D XR Cloud Streaming

Empowering BMW's New Strategy

Key Applications In BMW Smart Factory

Virtual Design and Testing

Enables real-time viewing and modification of car models in a virtual environment, accelerating design iterations.

Production Process Monitoring

Combines real-time factory data with 3D models for dynamic virtual factory environments, allowing immediate issue detection and resolution.

Training and Simulation

Facilitates employee training and production simulations through VR and AR devices, enhancing training efficiency and safety.

Showcase and Marketing

Enables immersive experiences in digital marketing, virtual showrooms, and test drives, offering flexible configuration options and cost-effective, imaginative marketing solutions.

LarkXR's Value Proposition to BMW Automotive Excellence

Enhanced Efficiency and Collaboration

Facilitates cross-departmental and cross-regional collaboration through high-fidelity, interactive 3D models accessible across various devices.

Flexible Deployment Options

Suitable for private, public, and hybrid cloud environments, supporting multiple business scenarios simultaneously.

Cost Reduction and Quality Improvement

Reduces physical testing needs and enables more precise design and optimization, ensuring high-quality standards across all stages.

High-Quality Visualization

Provides 4K and 8K ultra-high-definition visual effects for accurate design evaluation and early problem detection.

Real-time Data Processing and Visualization

Enables immediate monitoring of production status, allowing for quick adjustments and optimized resource allocation.

Rapid Deployment and Flexibility

Offers quick system setup, sometimes in as little as 30 minutes, allowing businesses to swiftly respond to market changes and internal demands.

LarkXR x Digital Twins in the Automotive Industry

The automotive industry is undergoing a rapid digital transformation, with digital twin technology and real-time cloud streaming at the forefront. These transformative technologies not only enhance research and production efficiency but also significantly reduce costs and improve product quality.

The synergy between LarkXR, Paraverse’s real-time cloud streaming solution and digital twin technology is accelerating the digital and intelligent transformation of traditional automotive manufacturing, addressing challenges in new vehicle development, quality assurance, and design optimization.

Paraverse, serving automotive and manufacturing industry leaders like BMW Brilliance, is pioneering the integration of these technologies to bridge the gap between virtual and physical realms in manufacturing. This technological synergy empowers automotive manufacturers to adapt to changing market demands and maintain a competitive edge in an increasingly digital world.

Paraverse Bridging the Physical and Virtual

Driving the Future of Automotive Manufacturing