In the era of rapid digital transformation, the manufacturing industry is undergoing a profound evolution driven by technological advancements. As businesses embrace the demands of an increasingly digitized society, they are investing significantly in innovative solutions that support their digital transformation (DX) initiatives. Decentralized rendering is among these groundbreaking solutions, holding immense potential to revolutionize the industrial sector and drive sustainable growth.

Revolutionizing Manufacturing: The Digital Transformation Edge

Manufacturing DX, known as digital transformation, involves incorporating digital technologies into manufacturing procedures, goods, and services. It enables manufacturers to streamline operations, enhance productivity, and improve decision-making by utilizing advancements such as cloud computing, IoT, big data analytics, and artificial intelligence (AI). Embracing DX allows manufacturers to gain a competitive advantage in the industry and establish a foundation for long-term growth.

The manufacturing landscape is witnessing a paradigm shift as technological advancements redefine the competitive terrain. Trends such as robotic manufacturing, sustainable technologies, and connected vehicles are shaping the industry. The value of digital transformation in the manufacturing sector was estimated at $263.9 billion in 2020 and is projected to reach $767.8 billion by 2026. Manufacturers recognize the importance of embracing digital transformation, with 91%¹ of executives foreseeing augmented reality/virtual reality (AR/VR) as pivotal in ensuring their company’s future success.

The Significance of Industrial AI in Driving Manufacturing DX

Industrial AI stands as a pivotal force propelling the digital transformation of the manufacturing industry. By harnessing the power of AI-driven machine learning algorithms, manufacturers can unlock a wealth of opportunities to analyze extensive datasets, glean invaluable insights, and revolutionize their operations. This transformative technology empowers manufacturers to automate mundane tasks, predict maintenance needs, optimize production schedules, and promptly identify quality issues in real time.

Industrial AI offers several key benefits to manufacturers:

- Predictive Maintenance: Industrial AI analyzes equipment data to forecast and prevent potential failures, minimizing downtime and reducing maintenance costs significantly. Predictive maintenance can slash maintenance costs by up to 30%, reduce downtime by 70%, and prolong equipment lifetime by 20%.²

- Process Optimization: AI plays a pivotal role in identifying inefficiencies within manufacturing processes and suggesting targeted improvements, thereby fostering heightened operational efficiency.

- Quality Control & Product Development: By swiftly identifying defects and irregularities in real time, AI elevates the standard of quality control, leading to an overall enhancement in product quality.

- Supply Chain Optimization: Through the analysis of supply chain data, AI optimizes inventory management, facilitates demand forecasting, and streamlines logistics, fortifying the entire supply chain.

- Predictive Maintenance: Industrial AI analyzes equipment data to forecast and prevent potential failures, minimizing downtime and reducing maintenance costs significantly. Predictive maintenance can slash maintenance costs by up to 30%, reduce downtime by 70%, and prolong equipment lifetime by 20%.²

- Process Optimization: AI plays a pivotal role in identifying inefficiencies within manufacturing processes and suggesting targeted improvements, thereby fostering heightened operational efficiency.

- Quality Control & Product Development: By swiftly identifying defects and irregularities in real time, AI elevates the standard of quality control, leading to an overall enhancement in product quality.

- Supply Chain Optimization: Through the analysis of supply chain data, AI optimizes inventory management, facilitates demand forecasting, and streamlines logistics, fortifying the entire supply chain.

While industrial AI offers immense potential, implementing manufacturing DX and industrial AI comes with its own set of challenges. Merging legacy systems with new digital technologies can lead to integration hurdles and compatibility issues. Resistance to change from employees accustomed to traditional manufacturing processes can also pose a challenge. Addressing data security and privacy concerns is crucial to maintaining the integrity and confidentiality of sensitive information. Overcoming these challenges is essential for manufacturers to fully leverage the benefits of industrial AI and achieve successful DX.

Decentralized Rendering : The Manufacturing DX Catalyst

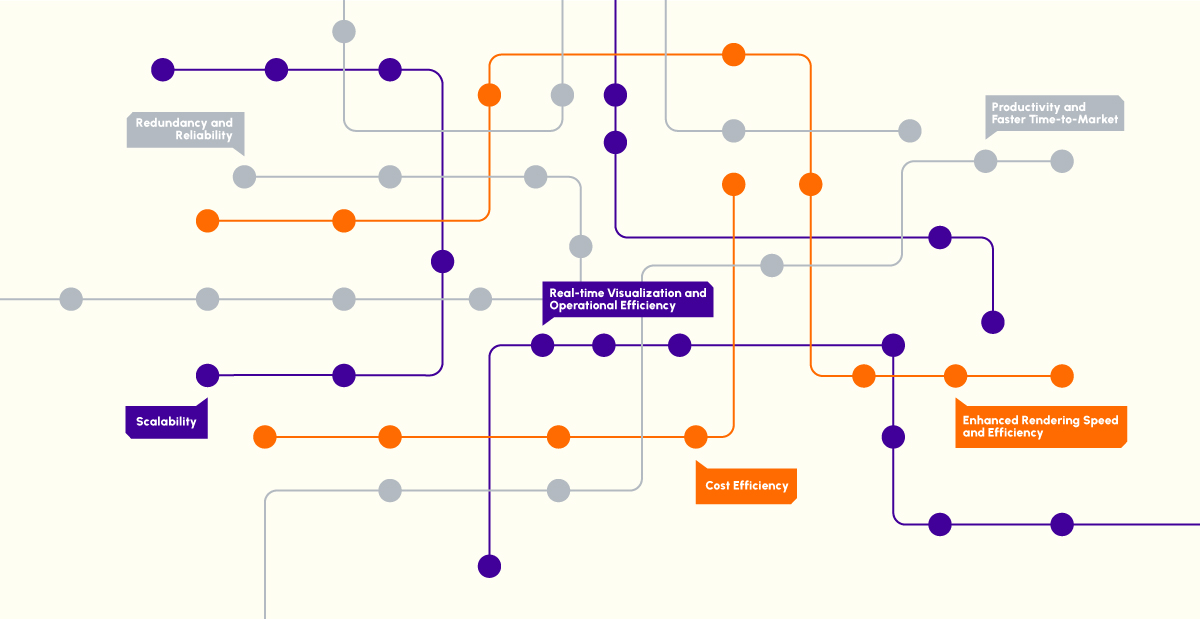

Decentralized rendering technology plays a pivotal role in empowering manufacturing DX and industrial AI. This innovative platform not only facilitates the seamless integration of industrial AI but also acts as a catalyst for enhancing digital operations and fostering innovation. Decentralized rendering offers several key advantages that can transform the manufacturing sector.

Enhanced Rendering Speed and Efficiency

A standout advantage of decentralized rendering technology is its capability to significantly enhance rendering speed and efficiency. Unlike traditional methods that require substantial computing power and time, decentralized rendering technology enables manufacturers to offload rendering tasks to a distributed network of computers. This results in a substantial increase in rendering speed and efficiency, effectively eliminating the bottlenecks associated with traditional methods.

Real-time Visualization and Operational Efficiency

Decentralization allows for localized access to rendering resources, reducing latency and improving the responsiveness of real-time visualization and analysis of manufacturing processes. This is crucial for monitoring instant manufacturing processes and analyzing production lines, equipment, and quality control. Real-time visualization and analysis enable manufacturers to make data-driven decisions based on real-time data, optimize processes, and improve overall operational efficiency.

Productivity and Faster Time-to-Market

Decentralized rendering technology enables seamless collaborative work among geographically dispersed teams, promoting flexibility in working on real-time rendering data. It provides manufacturers with agility in reducing rendering time for faster product development cycles, increased productivity, and the ability to adapt to changing production demands. This efficiency can streamline the manufacturing process and boost overall output.

Redundancy and Reliability

Decentralizing rendering tasks makes the system more resilient to failures, as tasks can be rerouted to other nodes in the event of a node failure, ensuring continuous rendering operations. This redundancy enhances the overall reliability of the rendering system, minimizing disruptions and leading to cost savings through optimized resource utilization.

Cost Efficiency

Traditional rendering methods often require expensive hardware and software investments. Decentralization can lead to cost savings by optimizing resource utilization and reducing reliance on expensive centralized infrastructure or local hardware. By offloading rendering tasks to the cloud, decentralized rendering offers a more cost-effective solution for rendering needs in manufacturing DX.

Scalability

The decentralized nature of real-time cloud rendering platforms allows for seamless scalability, enabling manufacturers to handle increased rendering demands without compromising performance. This scalability ensures that the rendering system can grow alongside manufacturing needs, maintaining efficiency and performance.

Unlocking New Possibilities for Manufacturers

Decentralized rendering technology has successfully bridged the gap between advanced rendering capabilities and manufacturing needs. By embracing this technology, manufacturers can unlock new possibilities for their digital transformation journey. They can tap into the potential of industrial AI, revolutionize their processes, and stay ahead of the competition in an increasingly digital landscape.

Transformative Applications: How Decentralized Rendering is Reshaping Manufacturing

The applications of decentralized rendering in manufacturing are vast. Here are a few examples that highlight the platform’s capabilities:

Product Design and Visualization

Manufacturers can utilize decentralized rendering platforms to render 3D models and visualizations of products. This enables designers and engineers to collaborate more effectively and make informed decisions on product design and development.

Virtual

Prototyping

Decentralized rendering capabilities allow manufacturers to create virtual prototypes of products. This enables design validation and testing before physical production, saving time and reducing costs associated with physical prototyping and testing.

Marketing and

Advertising

By leveraging decentralized rendering power, manufacturers can create high-quality visual content for marketing and advertising purposes. This enhances brand presence and attracts customers through engaging visual experiences.

Training and

Simulation

Rendering realistic training simulations enables manufacturers to train employees on complex processes or equipment without the need for physical setups. This saves costs and provides a safe environment for learning and skill development.

Product Design and Visualization

Manufacturers can utilize decentralized rendering platforms to render 3D models and visualizations of products. This enables designers and engineers to collaborate more effectively and make informed decisions on product design and development.

Virtual

Prototyping

Decentralized rendering capabilities allow manufacturers to create virtual prototypes of products. This enables design validation and testing before physical production, saving time and reducing costs associated with physical prototyping and testing.

Marketing and

Advertising

By leveraging decentralized rendering power, manufacturers can create high-quality visual content for marketing and advertising purposes. This enhances brand presence and attracts customers through engaging visual experiences.

Training and

Simulation

Rendering realistic training simulations enables manufacturers to train employees on complex processes or equipment without the need for physical setups. This saves costs and provides a safe environment for learning and skill development.

ParaLab: Pioneering Manufacturing DX with Decentralized Real-Time Cloud Rendering

ParaLab, Paraverse Technology’s decentralized real-time cloud rendering platform, offers a range of features and capabilities that empower manufacturers in their DX and industrial AI initiatives. Built on LarkXR, ParaLab provides manufacturers with a full-stack repository, rich API/SDK for second development, and a comprehensive set of functional components for enhanced rendering capabilities.

Some key features of ParaLab include:

- High-performance Real-Time Cloud Rendering Capability: Ensures ultra-low latency of less than 30 ms under dynamic bitrate conditions, enabling manufacturers to experience real-time rendering capabilities.

- Multi-GPU Resource Pooling Allocation, Utilization, and Acceleration: Optimizes resource utilization by pooling and allocating rendering tasks across multiple GPUs, enhancing rendering efficiency.

- No-Code Deployment: Offers an out-of-the-box feature set that allows manufacturers to deploy and utilize the platform without the need for extensive coding or technical expertise.

- Large-scale Commercialization: Supports high concurrency with over 20,000 sessions, making it suitable for large-scale commercial applications in the manufacturing industry.

- Compatibility: Be compatible with multiple engines, including 3D engines, web/applet, VR/AR/MR, Android/iOS apps, and Windows clients, providing manufacturers with flexibility and versatility in their rendering needs.

- Scalability: ParaLab’s decentralized nature enables seamless scalability, ensuring manufacturers can handle increased rendering demands without compromising performance.

With ParaLab, manufacturers can enhance their digital operations, unleash the power of industrial AI, and unlock new possibilities for their digital transformation journey.

Looking Ahead: The Expanding Horizon of Decentralized Rendering in Next-Gen Manufacturing and AI

Decentralized rendering emerges as a transformative force in the manufacturing sector, empowering manufacturing companies to embrace the digital revolution with unparalleled speed and efficiency. By adopting ParaLab’s innovative platform, manufacturers unlock the potential to make swift, data-driven decisions, automate complex processes, and significantly reduce operational costs. This not only enhances their competitive edge but also positions them as pioneers of innovation.

As the landscape of industrial AI and manufacturing DX evolves, the demand for decentralized rendering solutions is set to skyrocket, driven by continuous advancements in technology. Decentralized rendering is not just an option but a necessity for manufacturers aiming to thrive in the digitized future. It is a key driver for innovation, productivity, and competitiveness, marking a new era in manufacturing that is efficient, scalable, and cost-effective. In essence, decentralized rendering stands at the heart of the future’s manufacturing success, making it an indispensable tool for any forward-thinking manufacturer.

²PWC